AI Strengthens Patient Safety and Quality Control in Medical ManufacturingArtificial intelligence (AI) is beginning to play a pivotal role in medical device manufacturing, offering a solution to persistent labor shortages while significantly improving quality assurance. With its ability to perform full-scale inspection, AI is helping manufacturers deliver safer and more reliable products to patients.In an industry where errors can have life-threatening consequences, inspection has traditionally depended on skilled human technicians. Yet human judgment is susceptible to variation, fatigue, and subjectivity.

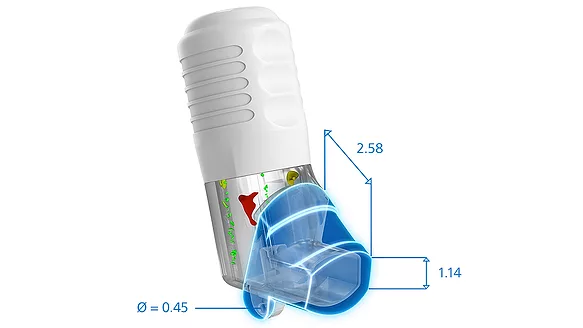

A technician’s eyesight, training, or endurance can influence outcomes, making complete reliability difficult to achieve. AI-powered inspection systems are addressing these limitations by applying deep learning algorithms to recognize features and defects with speed and consistency. Once trained on extensive image datasets, these systems are capable of achieving near-total accuracy and enabling 100 percent inspection rather than the traditional reliance on periodic sampling.The practical applications are already visible across a range of medical devices. Inhalers, which depend on precise pouching to deliver accurate doses of medication, can now be inspected in their entirety using CT imaging paired with AI models, ensuring consistent drug delivery to patients. Syringe manufacturers, who once had to compromise between sterility and inspection by opening seals, can now verify the presence and condition of components without breaking protective barriers. Similarly, surgical staples — produced in large volumes and critical in operating rooms — can be evaluated at scale, with AI-enabled CT systems separating and analyzing individual staples for defects.

Medical implants, which require specific coating textures to integrate with human tissue, are also benefiting from accelerated evaluation times: inspections that previously lasted close to an hour can now be completed in minutes.These advances do more than improve accuracy. By automating processes that previously demanded highly specialized oversight, AI reduces inspection times and expands capacity, helping manufacturers contend with the shortage of trained labor. Importantly, the technology does not displace human expertise but extends it, enabling professionals to focus on complex decision-making while leaving repetitive inspection tasks to automated systems.For patients and healthcare providers, the outcome is clear. By reinforcing inspection with AI, manufacturers can deliver devices with greater consistency and reliability, reducing the risk of failure in critical medical settings. For the industry, it marks a decisive step toward safeguarding quality at scale while adapting to modern workforce and production challenges

-

AI Strengthens Patient Safety and Quality Control in Medical Manufacturing

AI Strengthens Patient Safety and Quality Control in Medical ManufacturingArtificial intelligence (AI) is beginning to play a pivotal role in medical device manufacturing, offering